Cylinder Head Porting

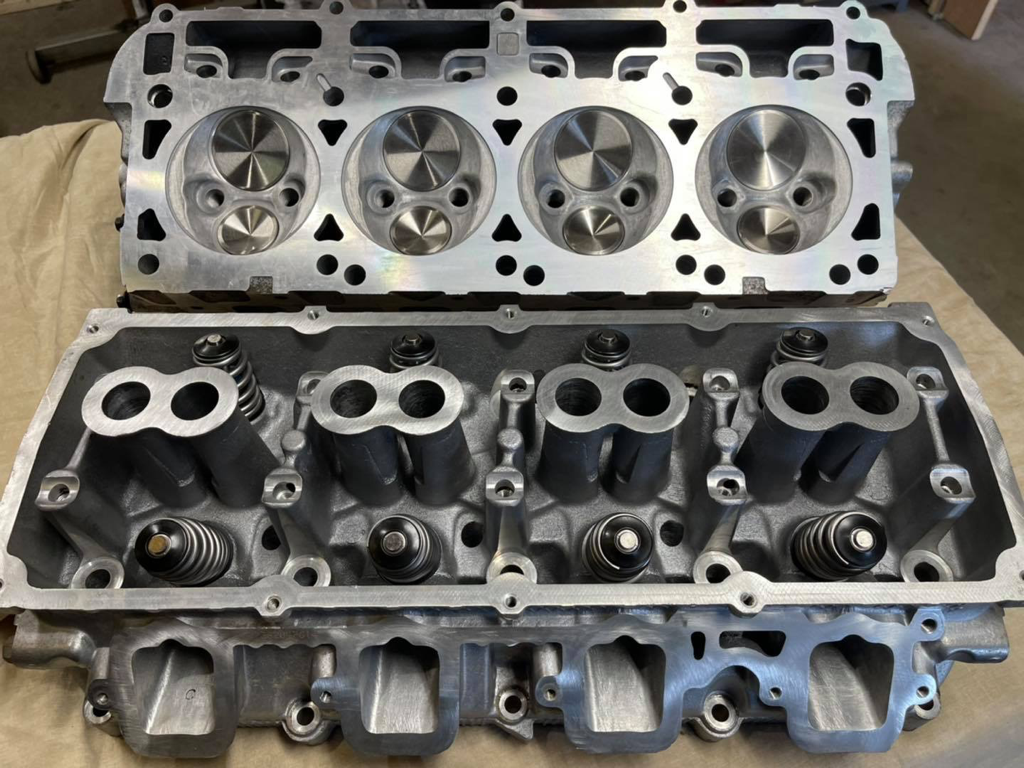

Porting & polishing a cylinder head is more than just opening up the ports as large as you can for the most max CFM possible. Each cylinder head is flow tested when it arrives for a baseline before porting work. We then take into consideration different parts of the engine combination including cubic inch, connecting rod length, & RPM, which helps us decide on the proper sizes and velocities of the port. Our swirl meter allows us to test the motion of the air entering the cylinder. That can help us decide how active and efficient the port is. Each porting job also includes a multi-angle valve job that uses specific angles for each engine application. This process is used in anything we do from a small engine to a full race engine.

Porting & polishing a cylinder head is more than just opening up the ports as large as you can for the most max CFM possible. Each cylinder head is flow tested when it arrives for a baseline before porting work. We then take into consideration different parts of the engine combination including cubic inch, connecting rod length, & RPM, which helps us decide on the proper sizes and velocities of the port. Our swirl meter allows us to test the motion of the air entering the cylinder. That can help us decide how active and efficient the port is. Each porting job also includes a multi-angle valve job that uses specific angles for each engine application. This process is used in anything we do from a small engine to a full race engine.

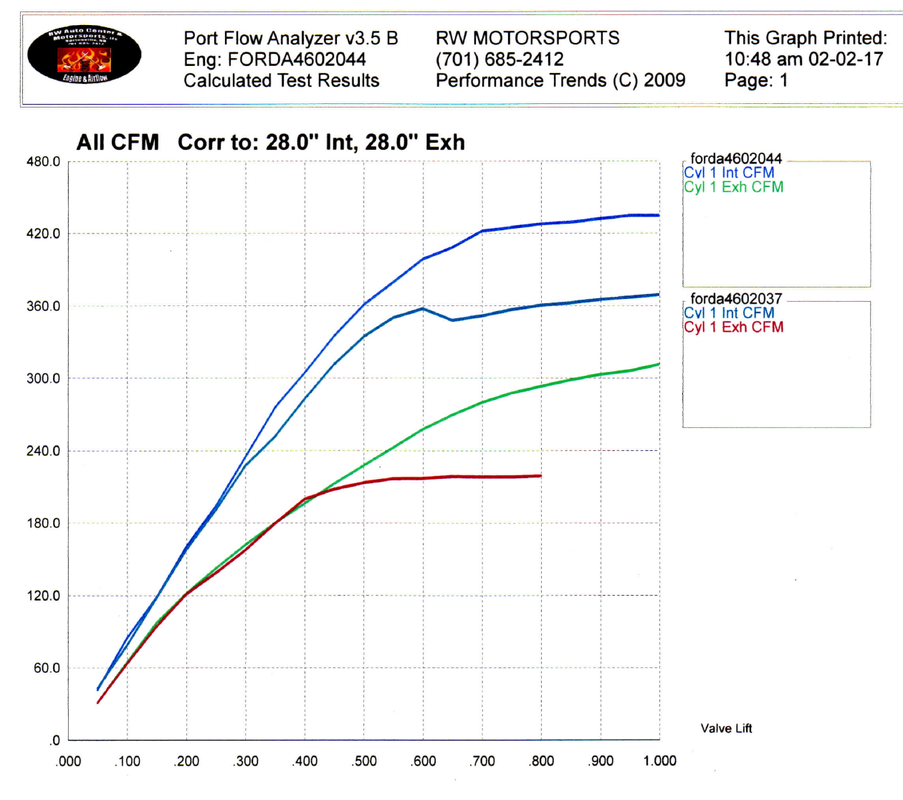

Example of a flow test showing airflow before & after work

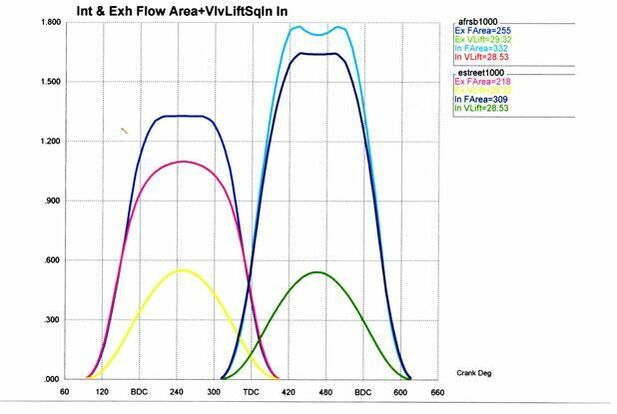

Example showing the flow area in the port vs the lift

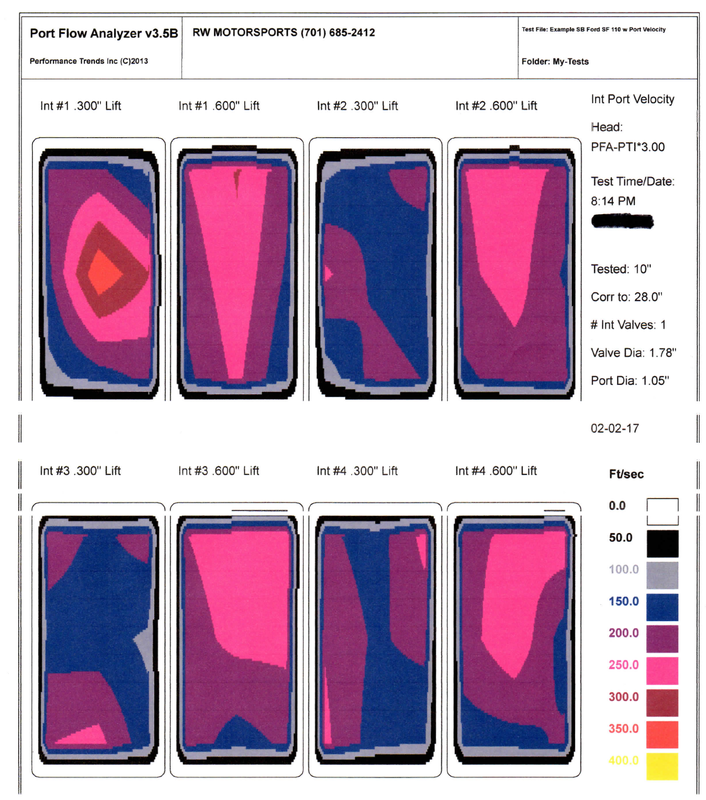

Example of velocity tested in a port

|

Intake Manifold Porting

We offer a few different methods of porting an intake manifold. We offer simply port matching the intake to the heads, minor plenum work, or even a full porting job including extensive plenum & port work. Each intake is flow tested and each port is matched as closely as possible to each other. |

Cylinder Head Reconditioning

- Pressure test or magnaflux to check for cracks

- Install valve guides or valve guide liners

- Install hardened valve seats

- Resurface (using updated CBN cutter for cast iron & PCD cutter for aluminum)

- Reface valves including backcut angles for better flow

- Each head when finished is vacuum tested for proper valve seal