Camshafts

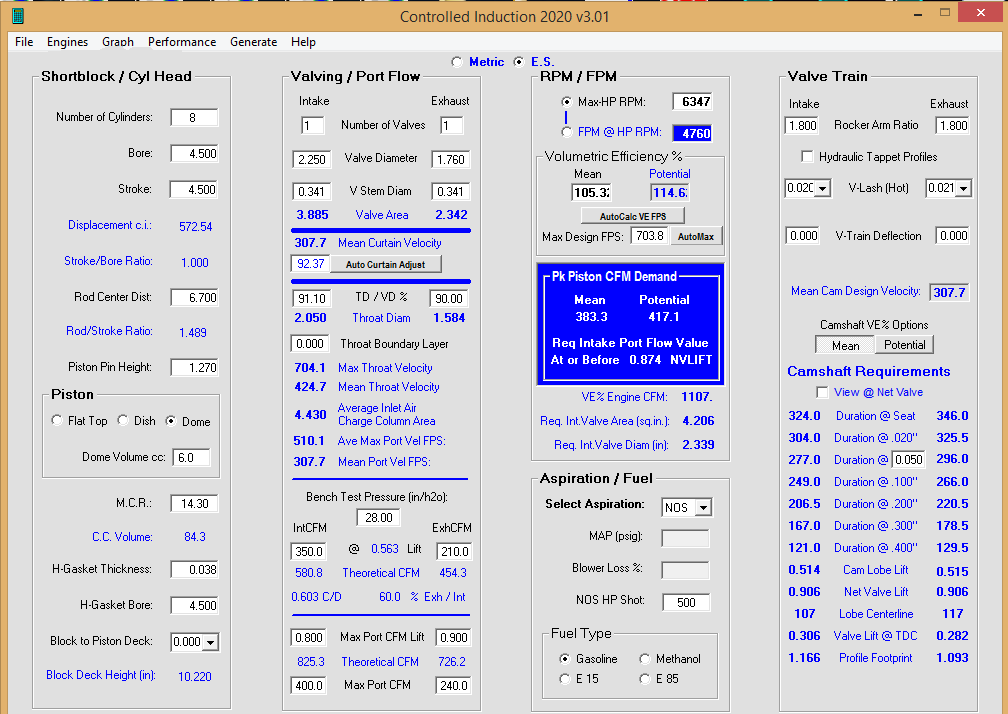

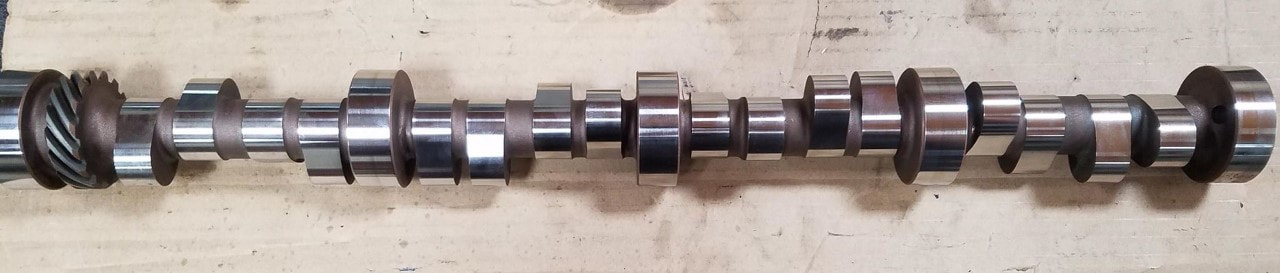

The camshaft is a very important part in making power in an engine. It controls when & how long the valves are open in the engine. Since the camshaft is the heart of the engine it is very important that it is working in perfect harmony with the other components in the engine. We us the Controlled Induction camshaft program to assist us in finding the perfect camshaft for your particular engine. We are able to enter all the parameters of the engine including the port sizes & velocities of the cylinder heads to help make a perfect combination of parts working together in the engine. We then are set up with Howards Cams which allows us to send Controlled Induction camshaft files directly to them and they will grind the camshaft to our exact specs for your particular engine.

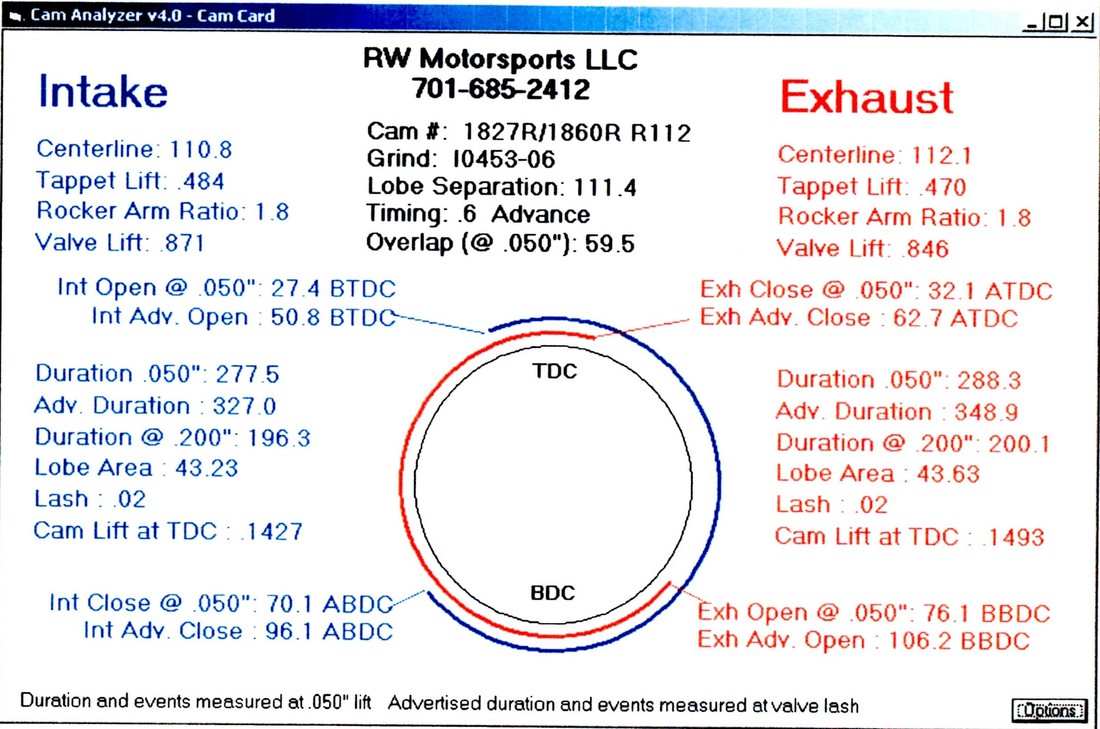

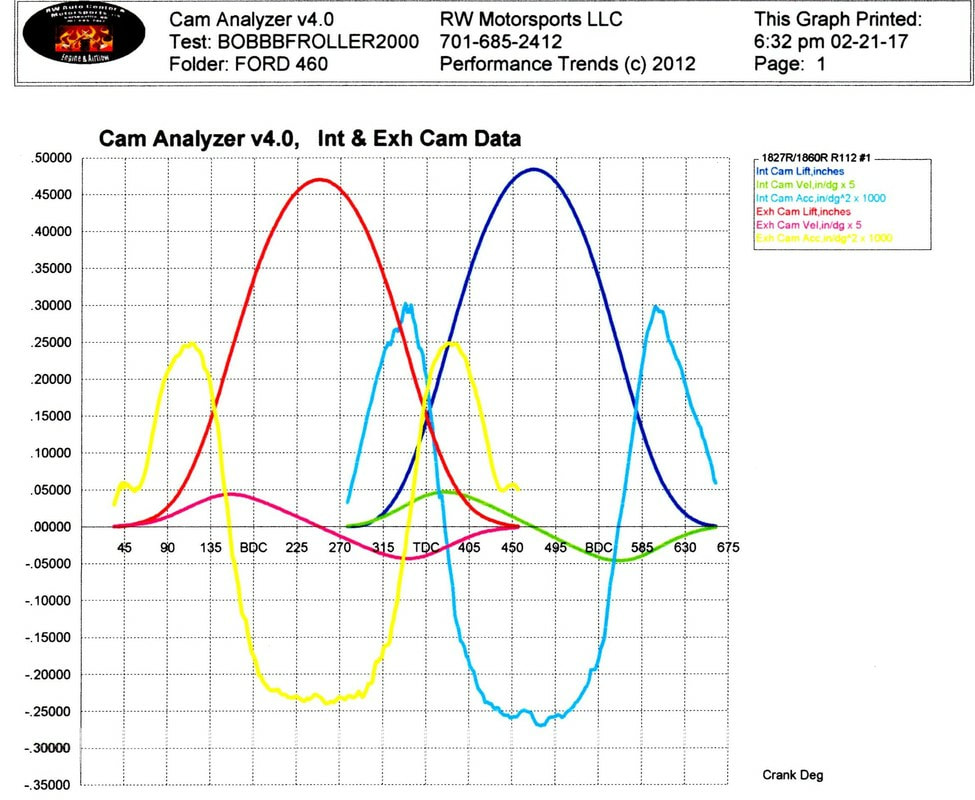

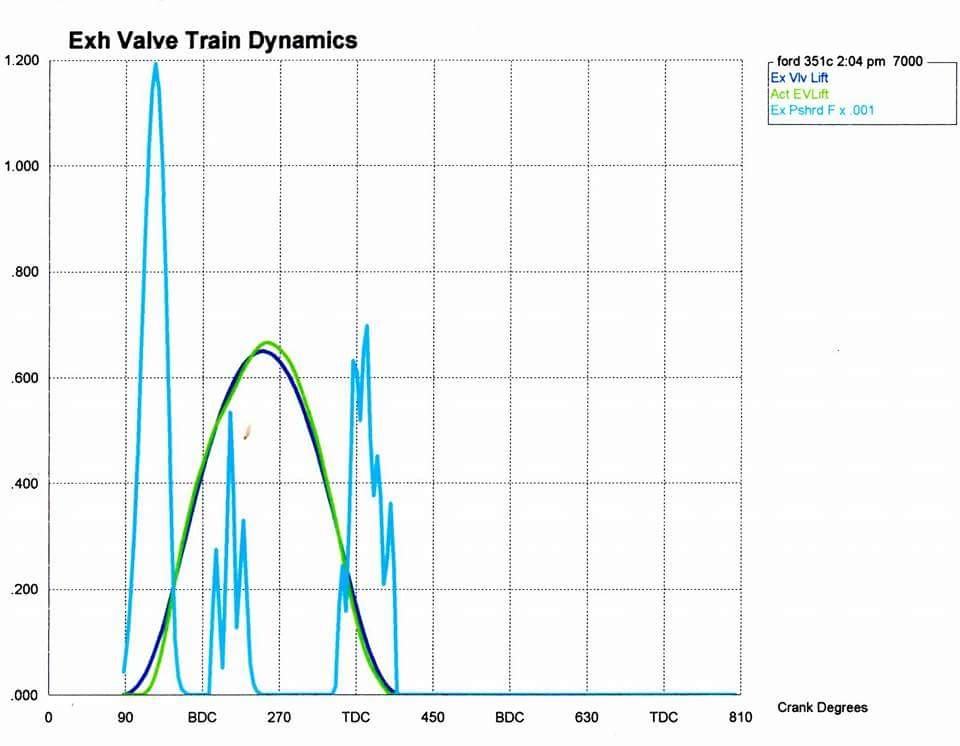

There is more to a camshaft then just the numbers on the cam card. Our camshaft test stand allows us to get a complete analysis of the lobe of the cam. We can find the lift of the lobe, centerlines & lobe separation, overlap of the camshaft, camshaft advance, opening & closing events of the camshaft and the lobe area to name a few. We then can use this information to help set up the valve springs to keep the valves under control. Our computer program will simulate to us if the valve is being tossed over the nose of the camshaft or if it is bouncing on the seat when it closes.

You can check out our camshaft recommendation page and fill out your information and we will be using our controlled induction program to help us pick out a camshaft for your exact engine!

The camshaft is a very important part in making power in an engine. It controls when & how long the valves are open in the engine. Since the camshaft is the heart of the engine it is very important that it is working in perfect harmony with the other components in the engine. We us the Controlled Induction camshaft program to assist us in finding the perfect camshaft for your particular engine. We are able to enter all the parameters of the engine including the port sizes & velocities of the cylinder heads to help make a perfect combination of parts working together in the engine. We then are set up with Howards Cams which allows us to send Controlled Induction camshaft files directly to them and they will grind the camshaft to our exact specs for your particular engine.

There is more to a camshaft then just the numbers on the cam card. Our camshaft test stand allows us to get a complete analysis of the lobe of the cam. We can find the lift of the lobe, centerlines & lobe separation, overlap of the camshaft, camshaft advance, opening & closing events of the camshaft and the lobe area to name a few. We then can use this information to help set up the valve springs to keep the valves under control. Our computer program will simulate to us if the valve is being tossed over the nose of the camshaft or if it is bouncing on the seat when it closes.

You can check out our camshaft recommendation page and fill out your information and we will be using our controlled induction program to help us pick out a camshaft for your exact engine!

Example of Controlled Induction Camshaft Selection

Example of a cam card that can be printed from our camshaft test stand

Example of lobe analysis telling lift, velocity, & acceleration

Valve Springs

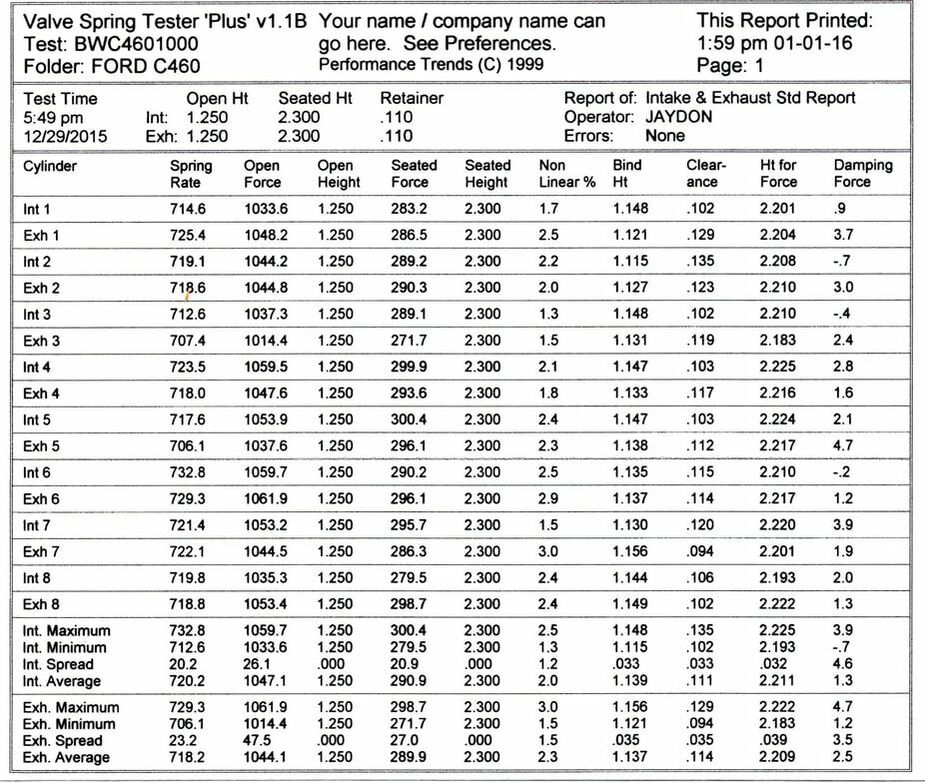

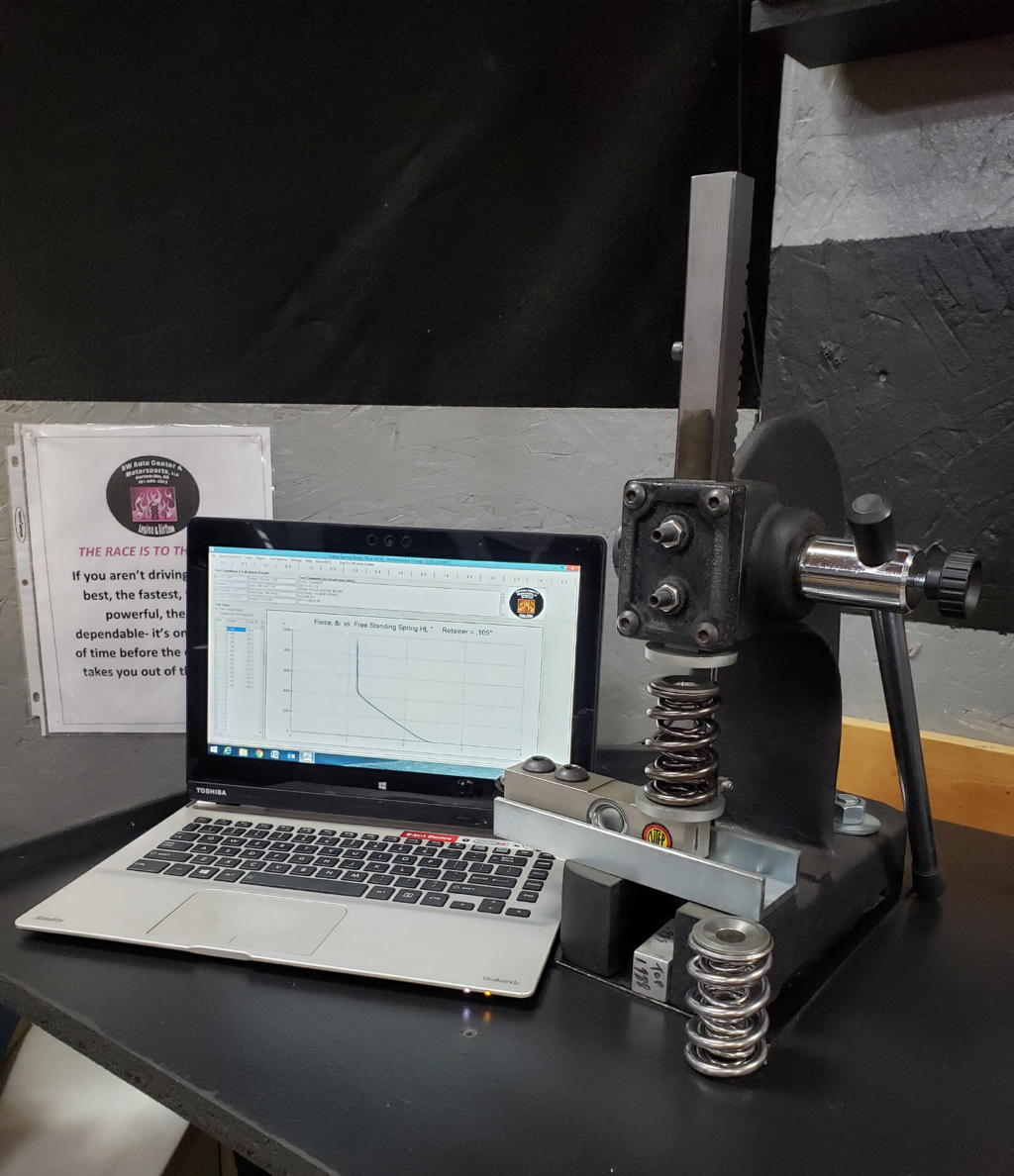

Our computerized valve spring tester allows us to test the pressures and different characteristics of a valve spring. We can test seat pressure, open pressure, spring rate, coil bind height, linearity of the valve spring, & the damping force of the valve spring. That then allows us to set up the installed heights on the cylinder heads for the correct valve spring pressures. We also believe that you want a valve spring to be set up as close to coil bind as safely possible to keep the harmonics out of the spring & keep the spring under control. We then can take all this information and overlay it on the camshaft profile to simulate what the valve spring may do on the engine. Another factor to consider is the weights of the valves, springs, retainers, & keepers. Titanium parts become very important when turning RPMs in an engine. The more weight you can get off the valve the more safely you can run higher RPMs.

Our computerized valve spring tester allows us to test the pressures and different characteristics of a valve spring. We can test seat pressure, open pressure, spring rate, coil bind height, linearity of the valve spring, & the damping force of the valve spring. That then allows us to set up the installed heights on the cylinder heads for the correct valve spring pressures. We also believe that you want a valve spring to be set up as close to coil bind as safely possible to keep the harmonics out of the spring & keep the spring under control. We then can take all this information and overlay it on the camshaft profile to simulate what the valve spring may do on the engine. Another factor to consider is the weights of the valves, springs, retainers, & keepers. Titanium parts become very important when turning RPMs in an engine. The more weight you can get off the valve the more safely you can run higher RPMs.

Example of a Valve Spring Test

Example of force on the pushrods & what happens when valve toss occurs